company insight

Your dry granulation experts

GERTEIS® is the leading quality supplier of premium roller compactors for dry granulation. With its innovative technological capabilities for design, development, manufacturing and process optimisation, GERTEIS® guarantees the optimal solution for your dry granulation processes.

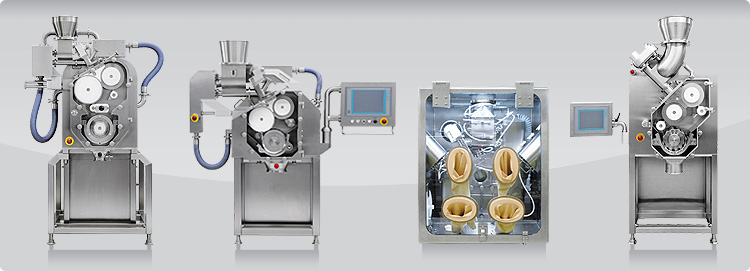

Roller compactors

With a dedicated focus on pharma industry and over thirty years of experience GERTEIS® delivers much more than just a machine with advanced roller compaction technology. Its innovative design and exact control system can process a more diverse range of powders than any other machine on the market.

Gerteis® provides support ranging through all phases from R&D, scale up and product transfer to manufacturing optimization and responsive sales services. This package makes GERTEIS® the industry’s leading partner for dry granulation.

Its innovative design and exact control system can process a more diverse range of powders than any other machine on the market.

Process understanding

The major advantages of Roller Compaction utilizing the Gerteis® Roller Compactors are:

- Using a few very accurate controllable process parameters, a reproducible continuous process can be achieved to provide an excellent opportunity for efficient development work.

- Producing a first set of trial granules for subsequent tableting takes just takes minutes and allows the Development Team to achieve all desired material properties, including flowability, particle size distribution and uniform ribbon density.

- Once the optimum parameters are determined by the QbD process, scale up to manufacturing size is easily attained due to the harmonised design principles used for all GERTEIS® roller compactors.

Roller compactor for dry granulation

GERTEIS® roller compactors measure up to the high quality requirements of the pharmaceutical industry. All machines in GERTEIS® are based on the unique inclined arrangement of press rollers allowing for best in class draw-in properties of even the most difficult powders. Precise side sealing systems in combination with side rim press rollers facilitate the uniform ribbon density which eliminates the need for recycling systems.

Several options for customising the machine to customer’s individual needs are available:

- Different press roller surface designs to overcome difficult material properties.

- Two granulator design options combined with various sieve mesh sizes and forms provide enhanced milling results and granule properties.

- Wet in place (WIP) and Clean in Place (CIP) solutions facilitate cleaning of the equipment while minimizing Operator contact with potent compounds.

- Press roller cooling or heating can be used when powders are thermally sensitive.

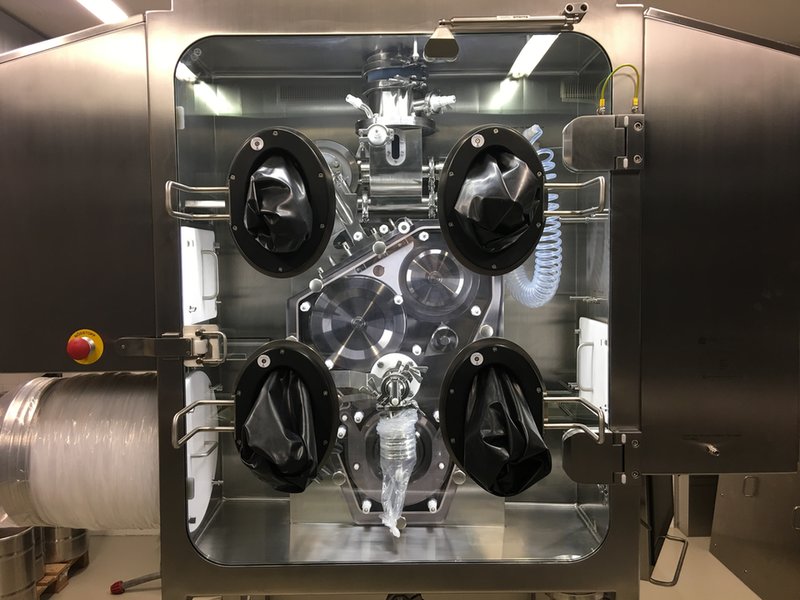

- Various high containment solutions are available down to OEB5 (0.1µg/m3). This includes ridged or flexible isolators with RTP ports.

Roller compactors for manufacturing

Heading up the GERTEIS® PACTOR® product line is the MACRO-PACTOR®. With production capacity of up to 400 kilograms an hour MACRO-PACTOR® is the choice for full scale production. This machine provides highest flexibility in order to tackle all production requirements while still allowing product development to be done using as little as 100g of product. The full range of customization options is available to find optimum setup for specific products.

Roller compactor for laboratory development

The MINI-PACTOR® is the tool to support pharmaceutical R&D work. With as few as 10 grams only, first trials can be started to investigate new material properties. By using GERTEIS® fast reaction gap control multiple samples of granules can be produced in a short period of time.

With a maximum output of up to 100kg/hr, the MINI-PACTOR® is not only a laboratory machine but also allows the customer to handle pilot projects and small-scale production. Scale-up to full-size production is easily attained due to the company’s harmonised PACTOR® designs.

Roller compactor for dangerous substances

GERTEIS® high-end roller compactor ULTRA-PACTOR® reaches a containment level of <0.1µg/m³. The ULTRA-PACTOR® guarantees optimal protection for the operator against highly active and dangerous substances.

Dry granulation service and support

GERTEIS® highly skilled staff is your partner throughout all phases.

Fully aware of the high regulatory requirements which are mandated in the pharmaceutical industry, GERTEIS® understand what it takes to not only supply a machine to its customers but to comply with GMP requirements and successfully execute validation processes in their own workshop and even more in customers facilities.

Training for all customer staff involved is available in user specific contents helping them to efficiently use the process and maximize its benefits.

Profit from proven project experience paired with in-depth process knowledge to exploit all roller compaction advantages:

Launch your product earlier to the market, boost your manufacturing or “get a grip” on your difficult products.

Contact GERTEIS® using the enquiry form to discuss your dry granulation application.

Go to top