Roller Compaction Technology Increasingly Important For Production Of Granules

Roller compaction is becoming an increasingly important agglomeration technology for the production of granules, as the pharmaceutical industry looks at ways in which it can introduce lean manufacturing to reduce its R&D and manufacturing costs.

GERTEIS® is a Swiss manufacturer of advanced high-quality roller compactors. GERTEIS® has set the standard with its unique dry granulation technology. The company’s understanding of the dry granulation process combined with patented roller compaction systems make GERTEIS® the technology leader in the field of dry granulation.

GERTEIS® has a depth of dry granulation knowledge and experience; its team of roller compaction specialists can evaluate an application and quickly predict and establish the best roller compaction parameters to achieve the optimum dry granulation process.

Gerteis Maschinen + Processengineering AG is the optimal solution for your dry granulation needs. From R&D trials to continuous manufacturing, Gerteis roller compactors can process powders, even those with extremely poor flow properties, far better than any other machine on the market, without the need for vacuum deaeration or roller cooling.

The Pactor line, which can be upgraded with High Containment as well as CIP for potent compounds, represent the best machines to launch a QbD program. Linear scale-up from R&D to high volume production has never been easier due to Gerteis’ sophisticated roller design.

In addition to any required Technical support, Gerteis is pleased to provide Formulation support to all of its customers.

Our product portfolio includes machines capable of product output ranging from 10g per trial up to 400kg / h.

Roller Compaction: Process Analytical Tools

The GERTEIS® roller compactors are able to control and measure all product quality relevant parameters (e.g. force, gap and roll speed) on-line in order to fulfill the requirements of the pharmaceutical industry for a well controlled and documented manufacturing process.

The GERTEIS® roller compactors are able to control and measure all product quality relevant parameters (e.g. force, gap and roll speed) on-line in order to fulfill the requirements of the pharmaceutical industry for a well controlled and documented manufacturing process. All the parameters are calibrated and validated. Additionally, in order to cope with batch to batch variations, our machines are fitted with control systems to allow equal granule properties during manufacturing according to PAT.

GERTEIS MASCHINEN + PROCESSENGINEERING AG had its beginnings as a one-man enterprise in Jona, Switzerland where the corporate headquarters is located to this day. Throughout the years the company grew exponentially and established itself as the market leader for premium dry granulation equipment. With our focus on roller compactors, we pride ourselves in possessing an in-depth knowledge on all aspects of dry granulation and the related processes which is much to the benefit of our customers.

Gerteis® – 30 Years

of Dedication to Quality

Gerteis Maschinen + Processengineering AG is proud to celebrate its 30th anniversary of providing the pharmaceutical community with high-quality roller compactors. The company based in Jona, Switzerland, was founded in 1986 by Paul Gerteis and has since become the market-leader in roller compaction and dry granulation units. The success of the company can be ascribed to a variety of reasons, not least of which are the values at the core of the enterprise; the reliability, sustainability and quality of its machines are the foundation of the company’s good reputation. Partnered with a dedication to service and customer satisfaction, Gerteis® is committed to maintaining the level

of excellence it has cultivated so far.

Looking back at the earliest years when the company was still a one-man-business, Paul Gerteis remembers the challenges of starting off in a field that already had long-established enterprises competing for a share in the market. His background in sales of pharmaceutical equipment provided Gerteis with an in-depth knowledge of the needs of his future customers and in what he calls a lucky coincidence he found a way to make roller compaction a viable and advantageous option for processing most substances. The development of the patented Gerteis compaction technology was only the first step in founding what is now a market-leading company. Customers had to be won and they were impressed by the numerous unique benefits offered by the Gerteis® roller compaction systems. It is in these early days that Paul Gerteis set the standard for the excellent customer service that the company still prides itself on today. “It was my personal commitment to serving the customer to the best of my ability that opened the doors to many of the companies we still supply today,” says Paul Gerteis in an interview. Word of mouth helped him establish his company which has seen a continuous growth since its founding days.

For the future of the company Paul Gerteis has one wish: “Customers have to be cared for with the same dedication we have provided so far and the passion for our product has to remain a driving force in our team.” While technological innovation and growth of the company are an essential part of the company’s plan for the next years, they are focused on optimising their existing systems and accommodating the individual needs of their customers. Having been a constant presence at pharmaceutical events and conventions, Gerteis aims to expand their Japanese market, to nfuse existing markets with new products and to be a larger presence in general.

Choosing a Gerteis® roller compactor is a long-term investment with some machines having been in use for more than two decades. This longevity is coupled with a high sustainability since the dry granulation process is a very energy-efficient and fast method to achieve a homogeneous granulate. The patented roller technology employed by all Gerteis compactors allows for a uniform consistency in the product and handles all products with the utmost care during the compaction process. Thanks to WIP (Wash in Place) and CIP (Clean in Place) systems available as part of most compactor series, down time needed for cleaning can be kept to a minimum. The CIP system in combination with Gerteis’ bespoke containment system ensures a high level of protection for the operators against dangerous substances.

The optimised rim assembly of the rolls guarantees the consistency of the product. Adjustments for many varying parameters are available making the compactors perfect for handling a myriad of products found in pharmaceutical and other businesses such as food processing or the chemical industry. Since all of the Pactor® and Polygran® series are designed for continuous production, a high output rate is possible. It is not only this which makes the compactors perfect for any company in the pharmaceutical market, but also the scalability of the machines, e.g. the Macro-Pactor® is capable of a throughput range from 100g per trial up to 400kg/h, which allows for a seamless transition from R&D to production.

To ensure the best possible service Gerteis is in constant exchange with engineers, scientists and suppliers to remain up-to-date with current trends, requirements and innovations. This translates into reliable expertise in finding optimal solutions for their customers’ production issues and increasing the existing output by optimising processes. Their customised designs are tailored to the needs of each customer and in-house training courses assure that operators are capable of handling and servicing the machines. Thanks to regional partners Gerteis is able to resolve maintenance issues and problems quickly and efficiently.

Acquiring a Gerteis roller compactor not only equips the client with a reliable machine, but also guarantees service which is second to none.

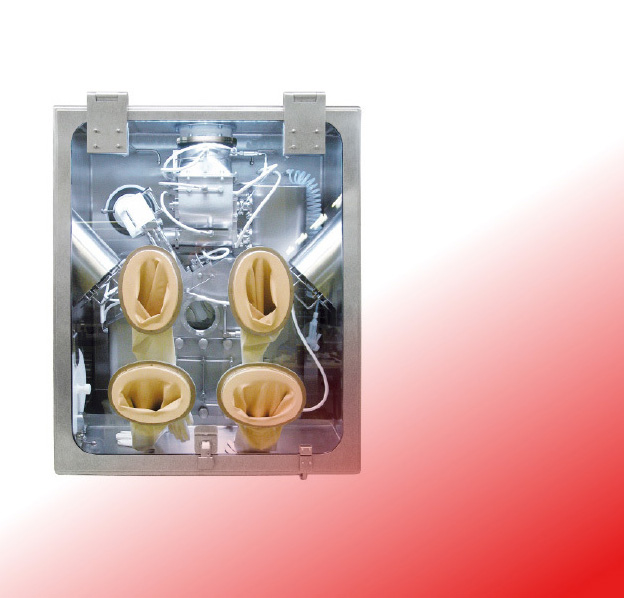

ULTRA-PACTOR® High Containment Roller Compactor

The ULTRA-PACTOR® High Containment Roller Compactor is the most technologically advanced roller compactor for optimal protection from highly active and hazardous substances.

High Containment Roller Compactor

The ULTRA-PACTOR® High Containment Roller Compactor is designed for full Cleaning-In-Place, so that operator contact with hazardous products is completely avoided. The ULTRA-PACTOR® roller compactor guarantees optimal protection for the operator against highly active and hazardous substances. With its ATEX-compliancy and the ability to purge N2 into the process area, this roller compactor truly pushes the boundaries in containment installations for dry granulation applications.

ULTRA-PRACTOR® is the most technologically advanced roller compactor that Gerteis® has produced. Building upon the well proven MACRO-PACTOR® - and with output capacities up to 400kg per hour - the ULTRA-PACTOR® is designed within an ergonomic containment isolator to allow processing of very potent products where high containment is required. In accordance with high containment good practice, the ULTRA-PACTOR® roller compactor is

ULTRA-PACTOR® Roller Compactor Features:

- Containment performance of <0.1 µg/m³>

- Ergonomically designed high containment isolator for the highest operator safety

- RTP ports for optimised operator handling

- Push-push filter designs

- Permanent online pressure monitoring for all seals and pressure zones

- Fully automatic Cleaning in Place

Roller Compaction Options

- Different roller surfaces

- Different granulator designs

- Built in PAT control system

- MES interface

- Variable screen mesh sizes

MACRO-PACTOR® Roller Compactor

Advanced Dry Granulation Technology

The MACRO-PACTOR® is the premium Gerteis® roller compactor with output capacity of up to 400kg per hour. However, as a fully continuous granulation process, amounts from as little of 100g can also be dry granulated, making the MACRO-PACTOR® suitable for development and pilot scale environments. Complete harmonisation with the other roller compactors within the PACTOR® range is assured with identical roller diameters. The result is that scale-up is straightforward, avoiding common problems associated with batch based processes, reducing material and API costs, and saving time to get the product to market quicker.

Unique Gerteis® Roller Compaction features

- Consistent feed system to the rollers with torque control of the screw feeder and tamp auger to ensure precision dosing of powder

- Angled compaction rollers to allow feed consistency, constant ribbon density and to minimise temperature gain.

- Free floating gap design and in-process force control producing a constant density ribbon

- Large diameter rollers to produce a longer dwell time in the nip area.

- Superior punch & die roller design to provide a constant density over the ribbon width and to virtually eliminate fines (no recirculation required!)

- Three stage milling process with the granulating oscillating mill with adjustable screen clearance, to produce a consistent and controllable particle size distribution.

- Full instrumentation with critical quality process parameter data-acquisition

- Full machine calibration

- Standard containment performance of 3 µg/m³ Time Weighted Average

MACRO-PACTOR® Roller Compactor Options

- WIP/CIP cleaning,

- Enhanced containment performance

- Build in PAT control systems

- Press roller cooling/heating

- Vacuum de-aeration.

- Different roller surface designs

- Separate feed funnel for small quantities.

- Industrial PC solutions

MINI-PACTOR® Roller Compactor

Advanced Dry Granulation Technology

The MINI-PACTOR® Roller Compactor is designed for both laboratory development and for small to medium scale production runs. Roller Compaction is a fully continuous granulation technology; the MINI-PACTOR® has capacities from 10 grams per trial up to 100kg per hour, and with harmonisation with the other PACTOR® designs by having identical roller diameters, scale-up is simple and quick, avoiding risks and reducing costs.

Unique Gerteis® Roller Compaction features

- Consistent feed system to the rollers with torque control of the screw feeder and tamp auger to ensure precision dosing of powder

- Angled compaction rollers to allow feed consistency, constant ribbon density and to minimise temperature gain.

- Free floating gap design and in-process force control producing a constant density ribbon

- Large diameter rollers to produce a longer dwell time in the nip area.

- Superior punch & die roller design to provide a constant density over the ribbon width and to virtually eliminate fines (no recirculation required!)

- Three stage milling process with the granulating oscillating mill with adjustable screen clearance, to produce a consistent and controllable particle size distribution.

- Full instrumentation with critical quality process parameter data-acquisition

- Full machine calibration

- Standard containment performance of 3 µg/m³ Time Weighted Average

MINI-PACTOR® Roller Compactor Options

- WIP/CIP cleaning,

- Enhanced containment performance

- Build in PAT control systems

- Press roller cooling/heating

- Vacuum de-aeration.

- Different roller surface designs

- Separate feed funnel for small quantities.

- Industrial PC solutions

POLYGRAN® Roller Compactor

The POLYGRAN® roller compactor offers outstanding value for money for such a sophisticated roller compactor that will deliver excellent dry granulation results.

Leaders in Roller Compactors

The POLYGRAN® roller compactor is the entry level Gerteis® roller compactor. The POLYGRAN® roller compactor is suitable for both development and production environments. This unique roller compactor features simplified handling and controls for an even easier accessibility. Maintaining the machine is effortless and an ideal machine for medium production quantities with a throughput of up to 300kg/h.

With many of the unique roller compactor technologies of the PACTOR® range included, the POLYGRAN® offers outstanding value for money for such a sophisticated roller compactor that will deliver excellent dry granulation results. With a capacity of 500g up to 300 kg per hour, the POLYGRAN® is suitable for both development and production environments.

POLYGRAN® Roller Compactor Features:

- Simple but accurate feed system to the rollers to ensure consistent dosing of powder to the rollers.

- Angled compaction rollers to allow feed consistency, constant ribbon density and to minimise temperature gain.

- Free floating gap design and in-process force control producing a constant density ribbon

- Large rollers diameters to produce a longer dwell time in the nip area.

- Simple but effective granulating oscillating mill with adjustable screen clearance, to produce a consistent and controllable particle size distribution.

- Full instrumentation with critical quality process parameter data-acquisition.

- Full machine calibration.

- Reduced number of interchangeable parts for easy disassembly and reassembly.

POLYGRAN® Roller Compaction Options:

- Different roller surfaces

- Variable screen meash sizes

- Operator interface with toruch screen panel

- Recipe managment

- Process data archiving

- CFR 21 Part 11 compliancy

- OPC-Connections

- Integrated 2-step granulation system

MINI-POLYGRAN® Roller Compactor

The MINI-POLYGRAN® roller compactor combines the ground-breaking GERTEIS® technology with an unprecedented mobility for roller compactors, making this roller compactor the perfect balance between performance and flexibility for your laboratory. The MINI-POLYGRAN® is the ideal roller compactor for laboratory development due to its capacity from 10 grams per trial up to 50kg/h.

Changeover from batch to batch can be completed in one of the industry’s fastest, due to the unique POLYGRAN® - setup of individual machine parts. Scale-up to production volumes can equally be achieved instantly and hassle-free.

Features & Benefits:

- Constant ribbon properties

- Controlled force and gap adjustment

- Fully instrumented

- New feeding system guarantees a constant powder feed per batch

- Validated force and gap measurement

- Longer dwell times due to the large roll diameter

- Constant product quality and properties

- Reduced Parts for rapid changeover and cleaning procedures

- Virtually no heat build-up with the Gerteis® patented roller design

- Convenient placement within the laboratory

- Easy scale-up to production batches

- Ideal for pharmaceutical, food and chemical laboratories

MINI-POLYGRAN® Roller Compactor Options:

- WIP cleaning

- Vacuum deaeration

- Different roller surfaces

- Integrated 2-step granulation system

- Separate feed funnel for small quantities

- Operator interface with industrial PC solutions

INTERPHEX JAPAN

Japan

27th – 29th June 2018

GERTEIS Seminar

17th – 19th September 2018

17th – 21th September 2018

Pharmtech Russia

Moscow, Russia

20th – 23th November 2018

PMEC India

Hall 10, Booth B17, Delhi

12th – 14th December 2018

ACHEMA GERMANY

Hall 3.0 D25

11th – 15th June 2018

INTERPHEX USA

Booth 1952

17th – 19th April 2018

Roller Compaction Seminars

The 2018 Gerteis roller compaction seminars have been a great success. Both seminars were held in September at Gerteis Jona with an international group of attendees. The first seminar in 2018 with the title 'Understanding Roller Compaction Technology' covered all aspects of roller compaction. Starting from the machine setup via the process parameter and trouble shooting. The second seminar 'First Roller Compaction Trials in Development of Dry Granulates' covered the basics for roller compaction development work, scale up and other related topics. All participants had hands on experience with the Gerteis development roller compactor and the production roller compactor during the seminars. We are happy to have hosted many interesting professionals from the industry and to provide an extensive insight into Gerteis’ dry granulation technology. We thank all our guests for their engaging participation and we look forward to see all again in 2019. We would like to thank our guest speakers from the industry as well.