Company Insight

Sponsored by B Medical Systems

B Medical Systems’ U701V: Reliable Ultra Low Freezer for Intensive Use

Safeguarding the integrity of biological samples and temperature-sensitive materials is critical, and Ultra-Low Freezers (ULTs) are used to ensure sample integrity at low temperatures.

Main image credit:

While reliable performance has always been essential for Ultra-Low-Temperature freezers, today’s evolving customer expectations demand that this reliability be delivered sustainably, even under intensive use. U701V, the new Ultra-Low-Temperature Freezer using variable-speed technology from B Medical Systems, represents the perfect balance of reliability and sustainability, offering uncompromised performance even during intensive use.

Ultra-Low Temperature (ULT) freezers are intended to store temperature-sensitive specimens and materials at low temperatures, as low as -80°C. They play a critical role in preserving the viability and integrity of temperature-sensitive specimens for long-term research and clinical use. Commonly found in laboratories, biobanks, and pharmaceutical settings, ULTs are designed with superior refrigeration technology and advanced insulation to ensure the intended storage temperature range.

ULTs are usually used for preserving critical biological materials such as vaccines, enzymes, cell cultures, and genetic samples, often worth millions or irreplaceable scientific value. Hence, the reliability of ULTs directly impacts research outcomes, scientific and medical research success, and regulatory compliance. Even a slight temperature fluctuation can compromise sample integrity and result in substantial financial and scientific losses. While traditional reliability ensures consistent performance, what is increasingly vital in today’s research and clinical environments is delivering that same reliability in an energy-efficient manner, especially during periods of intensive use.

The Challenges of Intensive Use

Intensive use of ULTs is widespread in clinical labs, pharmaceutical R&D, and biobanking operations where multiple users access the freezer, when there is high sample rotation or the facility has time-sensitive/high-throughput workflows. Some examples of intensive use are:

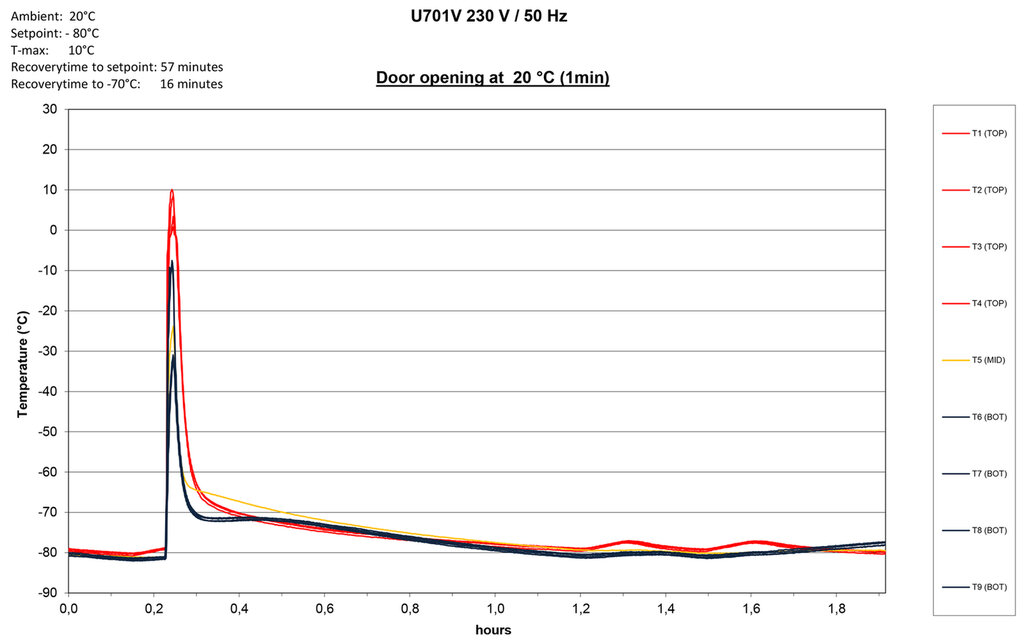

- Frequent door openings: High sample turnover, ongoing sample management, and inventory checks, etc, can lead to the freezer door being opened numerous times daily.

- Extended door openings: When freezers are fully loaded or in case of poor sample organization inside the freezer, sample retrieval can take longer, leaving doors open for extended periods.

- Adverse environmental conditions: Although not a user-generated condition, factors like high ambient temperature can stress the freezer’s cooling system.

These intensive conditions can result in temperature fluctuations, frost buildup, increased energy consumption, and mechanical wear and tear, all of which impact the reliability and longevity of ULTs.

Intensive Use and Energy Efficiency

In today’s research and clinical settings, energy efficiency is essential—not only to reduce operational costs, but also to support sustainability goals and lower environmental impact, without compromising performance. It must be noted that intensive use can significantly increase the energy consumption due to the added strain placed on the cooling system to maintain the intended internal temperatures. These intensive use conditions expose the interior of Ultra-Low Temperature Freezers to ambient air, causing temperature variations. In response, the cooling system has to work harder and more frequently to recover and stabilize the ultra-low freezer setpoint, typically around -80°C. This not only elevates energy usage but can also shorten the lifespan of mechanical components if the freezer isn’t designed to handle such demands. As a result, energy consumption and efficiency in high-usage scenarios are becoming a crucial factor in ULT freezer performance and lab sustainability. As energy prices rise and carbon footprints are scrutinized, ULT freezers that combine robust reliability with energy efficiency are no longer a luxury—they are essential infrastructure for modern science.

B Medical Systems’ U701V: A Reliable and Sustainable Solution

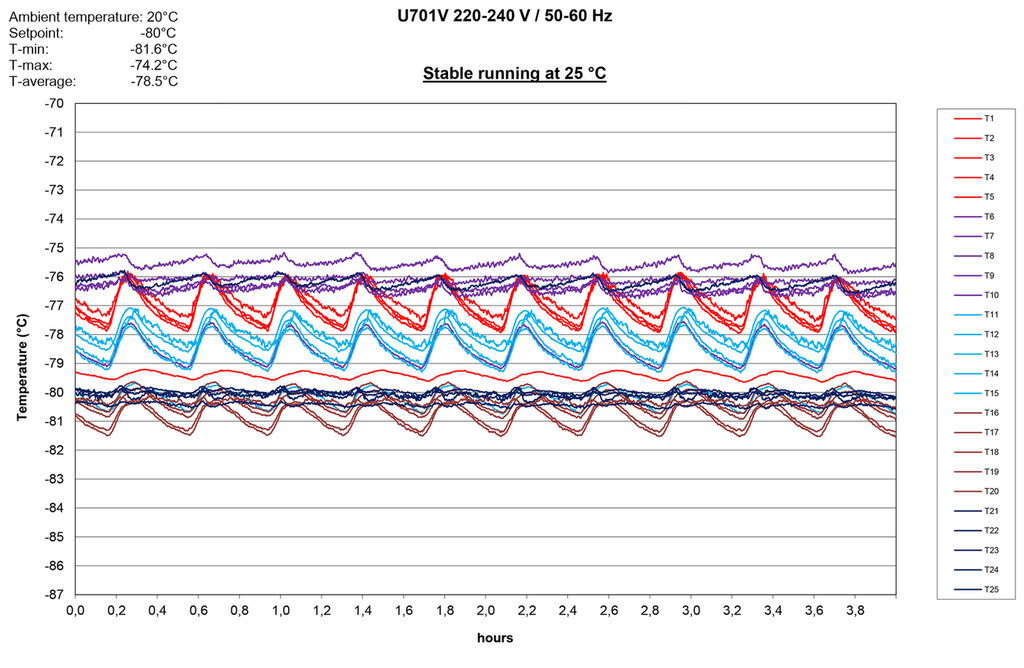

B Medical Systems, a leading manufacturer of vaccine cold chain and medical refrigeration solutions, has launched U701V, an advanced Ultra-Low Temperature Freezer that offers reliability along with energy efficiency even under intensive use. Designed using a variable speed compressor, U701V offers an operating temperature range of -86°C to -20°C and delivers an energy efficient performance while delivering superior temperature uniformity and rapid Door Opening Recovery (DOR). Certified as an EU MDR(Regulation (EU) 2017/745) Class IIa device, the U701V has an SN/T climate classification, ensuring a reliable and efficient operation even in ambient temperatures reaching as high as +43°C. Moreover, the U701V utilizes natural hydrocarbon refrigerants, which have a much lower environmental impact than conventional refrigerants.

The U701V represents a new standard in Ultra-Low Temperature Freezers, meeting the evolving reliability and sustainability needs. By integrating superior variable speed cooling technology, advanced insulation, adaptable temperature range, energy-saving features, and eco-friendly refrigerants, B Medical Systems has created a solution that supports the customer requirements of having a perfect balance of reliability and sustainability, offering uncompromised performance even during intensive use.

Contact information

B Medical Systems

17, op der Hei

L-9809 Hosingen

Luxembourg

Tel.: +352 92 07 31 1

Email: info@bmedicalsystems.com

Web: www.bmedicalsystems.com

- Biffa internal savings data, average saving (January - August 2023)

- Nisbets internal savings data, average saving (January – September 2023)

- Compliance365 internal data, average savings

- HEINEKEN UK data, Calculations based on SmartDispense® active accounts each year since 2015 with 10 lines

- Independent test results based on subterranean and ground floor pub cellars of varying sizes

- Independent test results based on subterranean and ground floor pub cellars of varying sizes