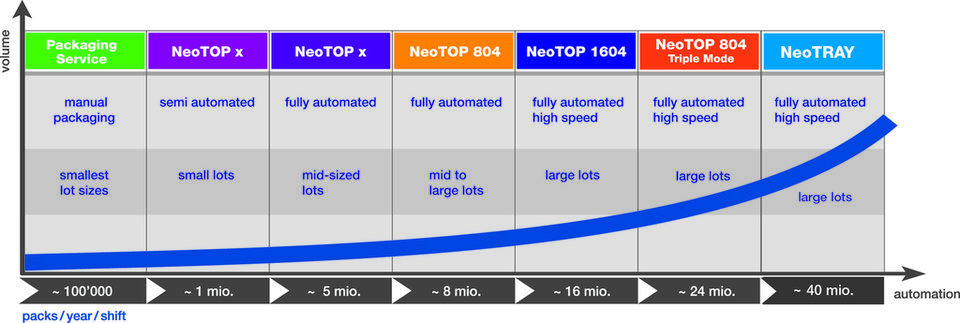

Dividella accelerates high-output packaging with new NeoTRAY flagship cartoner

>

The NeoTRAY sets a further ‘first’ in being able to operate in both sensitive top-loading and fast side-loading in continuous motion.

The modular system allows for a broad range of applications for high volumes. It is particularly suitable for packaging parenteral administration forms including vials, syringes, injectors, pens, ampoules and cartridges as well as inhalers, nasal sprays and other applications.

NeoTRAY combines the recognized production and environmental advantages of 100% mono-material packs with Dividella's emphasis on modular design and engineering and 40-year experience in product handling to provide highly adaptable and customized feeding systems.

MORE INFO

The best of two worlds combined

Previous machines have optimized for either side-loading or top-loading, to work either especially quickly or especially gently, with manufacturers forced to trade-off flexibility against performance. The NeoTRAY combines the best of both worlds in one machine. “With our patented top-loading technology, the products are gently placed into the open trays from above. Fast side-loading can manage large volumes of a wide variety of parenterals,” Christoph Hammer, Dividella CEO, added.

The NeoTRAY saves time and money: at high speed, the efficient cartoning machine processes up to 400 individual products or multipacks per minute while reliably adapting to a best-in-class range of individual product package and multipacks formats ranging in size from 65x35x15 mm to 200x150x 110 mm.

To meet current and future regulatory requirements, the NeoTRAY also offers integrated solutions for tamper evidence, child safety and Track & Trace functions.

About NeoTRAY

NeoTRAY combines the best of both top-loading and side-loading cartoning technologies in one machine. With patented top-loading technology, the products are gently placed into the open trays from above. Fast side-loading can manage large volumes of a wide variety of parenterals.

NeoTRAY is designed to use 100 per cent monomaterials for more efficient and cost-saving packaging of the highest quality.

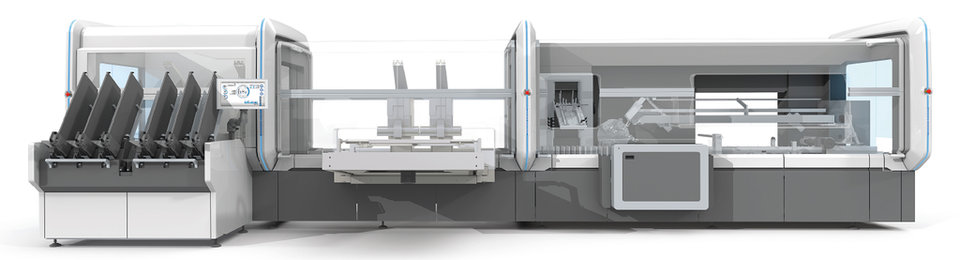

Tray Forming Module: This section feeds and forms trays from pre-glued die-cut blanks, with magazines positioned for high visibility and ease of access.

Top-Loading Module: Dividella’s state of the art infeeding systems top-load the products in a continuous motion into the erected trays. This module also performs other in line operations such as: checking machine readable codes, verifying tray contents and variable data, inserting leaflets and/or booklets, and printing/marking alphanumeric text and coding on the package.

Side-Loading Module: After inserting of all products, the erected and filled trays arrive via stacking conveyor at the Continuous Motion Cartoner where packages can be closed in various ways, using hotmelt, or fugitive glue, with or without tamper evidence or tuck in flaps.

The NeoTRAY features GMP compliant construction, conforming to Directive 2011/62/EU

ABOUT DIVIDELLA

Dividella AG, a member of the Korber Medipak Systems Group, specializes in developing and manufacturing packaging machinery for the pharmaceutical industry with specific expertise in packaging requirements for parenteral products. Based at Grabs in the canton of St. Gallen in eastern Switzerland, Dividella counts 20 of the world’s largest pharmaceutical companies among its clients, including the entire top ten.

For four decades, Dividella has provided distinctive and highly effective solutions for secure and flexible packaging of pharmaceutical products. Its patented top-loading system forms the basis for solutions that have continually evolved to provide the most up-to-date, patient-friendly and environmentally responsible solutions for parenteral packaging.

Dividella provides complete secondary packaging solutions for medicinal products that can be difficult to stack, such as needles, injector pens, vials and syringes. Its top-loading solution enables product handling with extreme care and safety. Dividella patented feeding systems guarantee products are handled with care while maintaining high output.

www.dividella.com