company insight

Mecmesin: Versatile testing systems for the pharma and medical device industry.

Mecmesin design and manufacture force and torque test systems that are accurate, reliable and excellent value for money. Physical testing of your products and materials ensures regulatory compliance and protection of brand reputation. Leading names in the production of pharmaceuticals, packaging and medical devices are testing to perfection with Mecmesin.

Achieving compliance with local requirements can be a tough deal and an unexpected challenge sometimes

Our background

Mecmesin is UK-headquartered, with subsidiary companies in Europe, USA and Asia, plus a worldwide distributor network. We operate under ISO 9001 quality standards, and for over 40 years our solutions have been used to guarantee the quality of finished products and materials from the R&D laboratory to the factory floor.

Mecmesin also supplies fixtures and a range of dedicated testers, designed to test to international regulatory standards. Our engineers can also design and manufacture bespoke solutions to meet your unique criteria.

We offer simple hand-held instruments to fully-comprehensive computer-controlled systems to suit many test applications, budgets and changing needs.

Your benefits

Gaining an in-house capability for quality assurance, rather than outsourcing, is a major cost reduction benefit we see for many customers. Medical devices are often assemblies comprised of a number of individual components. Should a seal be out of alignment, the device may not function correctly and maintain its performance. Our instruments can display an instant, pass/fail indication against defined criteria, immediately flagging a potential problem with a source of supply.

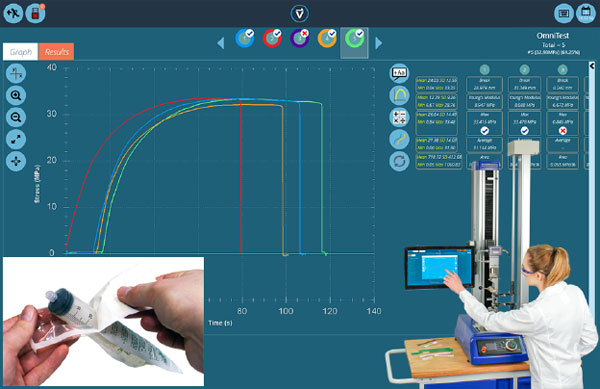

Our touch screen and computer-controlled systems display the test graphically, which gives valuable insight into the performance of the individual sample and the ability to quickly compare against samples from other batches.

Pharmaceutical solutions

Our VectorProTM software was developed with pharmaceutical industry legislation in mind. It incorporates operator permissions security, audit trail features and database architecture to support FDA 21 CFR Part 11 compliance environments.

In a highly regulated industry, safety-driven compliance impacts all areas of the supply chain from initial stages of drug development to point of administration to the patient. Standards bodies such as the European Pharmacopoeia (Ph. Eur.), US Pharmacopoeia (USP), ASTM, ISO, EN and FDA cover everything from packaging, drug delivery devices to pharmaceutical product design and formulation. Our customers appreciate the versatility of Mecmesin equipment to test to these standards.

Packaging focus

For primary, secondary and tertiary pharmaceutical packaging the design brief is to quantify the balance between strength and security and accessibility at time of need. Sterility is paramount, with materials providing a breathable microbial barrier, yet providing tear and puncture resistance plus seal integrity.

A familiar primary packaging solution is the blister pack design. Peel testing equipment must be able to hold the flexible or semi-rigid container without deformation whilst peeling the protective foil at the required angle to accurately evaluate its openability.

Containment systems for sharps and bulky medical devices must undergo penetration resistance checks. Both the designed package and its raw materials can be strength tested for suitability by using the appropriate Mecmesin tester and grips.

Pharmaceutical closures have complex designs to ensure security and safe use. Mecmesin has a wealth of expertise in testing the application and removal torque of a variety of tamper-evident and Child-Resistant Closures (CRC) with the ability to produce a custom mandrel for your specific design of closure; often essential to maximise repeatability when testing. The requirement to apply an axial force and torque simultaneously is met by our Vortex system; its motor drive providing constant rotational speed control for the ultimate in repeatability and accuracy. Its software detects and analyses the events which occur during the interaction of the closure with the container so that you can determine the overall performance.

Medical devices focus

Established international standards for medical devices make sure that they are functional under correct usage conditions and resistant to failure and inadvertent disassembly. The ubiquitous Luer type conical taper connector is used in many applications, requiring versatile torque testing equipment to perform operational checks even at the lowest of loads.

Instruments for drug delivery have mechanisms which must be secure yet easy to activate. This may be the effort required to rotate a dial or pull a trigger. Often these loads are quite light, such as the dosage control for an insulin injector pen. Our Helixa torque testing system is designed to precisely measure low torque values and ensures exact axial alignment of the rotating parts.

Pharma products focus

Mecmesin systems can also test the physical properties of solid and semi-solid pharmaceutical products. The hardness of tablets has implications for resilience during transport and ease of snapping, which must be balanced with dissolution properties. Our systems can measure the peak compressive force to snap or to crush. Gels and creams can also be tested for their consistency and flow characteristics – the texture influencing processing machine parameters and end user application—enabling manufacturers to quantify the impact of different formulations.

Whatever your speciality, Mecmesin has the versatile tester to help you enhance your quality.

For more information about

Mecmesin

Spring Copse Business Park, Slinfold,

West Sussex, RH13 0SZ, United Kingdom

Go to top