BEA TECHNOLOGIES S.p.A.

CONSTANT INNOVATION: BEA Technologies is a leader in the production of filter elements with high capacity nanofibers for the purification of chemical-pharmaceutical products, liquid and viscous products.

In the field of filtration and purification for pharmaceutical applications, BEA Technologies, an Italian company with a strong international presence, has built up a notable experience in the production of filters with nanofibers, offers customized and innovative solutions.

BEA Technologies, an Italian company with a strong international presence, is among the leaders in Europe in the production of filters with nanofibers. In the field of supply to the pharmaceutical companies, BEA Technologies offers customized and innovative solutions in the filtration of liquid and "critical" products.

The company is able to offer the most suitable products for the solution of a wide range of specific filtration problems, which can also be customized on the basis of the most challenging customer needs. Among the proposed filtration solutions, high-performance filtration systems for the pharmaceutical sector have been developed, in particular the new line of filter elements that incorporate nanofibers with high capacity. The Italian company meets the demands of the pharmaceutical sector: “We offer nanofiber products, specific for pharmaceutical applications ”, declares Mr. Roberto Bea, President of BEA Technologies, who considers Research and Development processes as the key to success. “Our purpose is to become a leader of the European market in the supply of filtration products intended for this sector; our efforts are dedicated to the consolidation of our position as significant players worldwide”.

Among the solutions proposed by the company, which in recent years has focused on the application of nanofibers to the development of new products for the pharmaceutical industry, new high-performance filtration systems and products are announced.

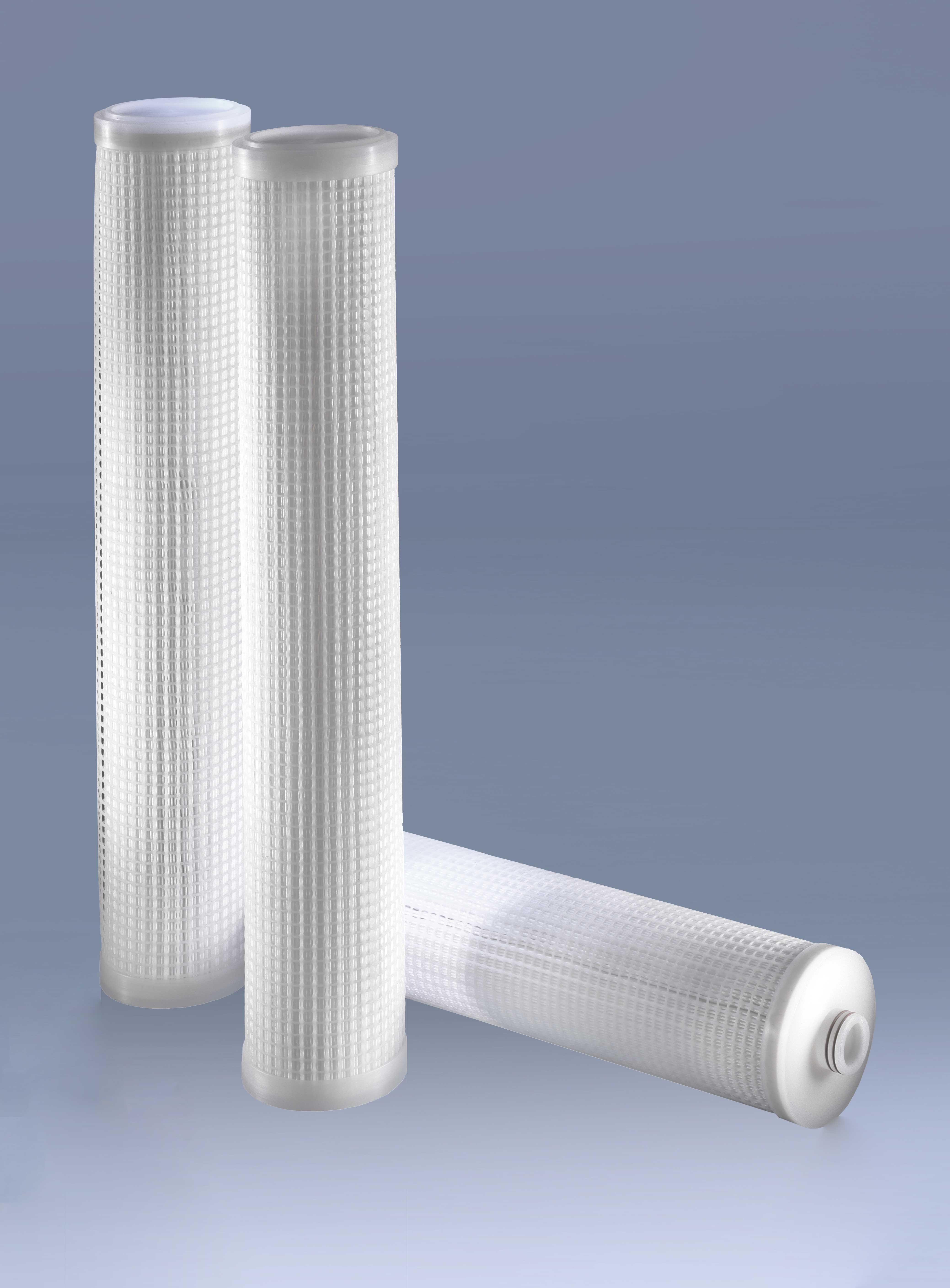

BEA Technologies offers three series of filter elements with nanofibers called MAGNEX, NANOTRAK and NOVATRAK, that meet the needs of companies engaged in the production of new generation drugs (which have a high degree of sensitivity during the production process). The production of the filter elements is carried out in controlled atmosphere environments (clean room), in compliance with GMP guidelines, to guarantee the high level of quality required by biological applications typical of the pharmaceutical sector.

Extending the “service life” of the filter elements is one of the main objectives pursued in the company’s research. The aim is to ensure optimal operation in demanding use situations and for the purification of "critical" or viscous products.

Critical microfiltration products are produced in a controlled atmosphere environment (clean room) and in compliance with the GMP guidelines, to ensure a high level of quality and cleanliness for biological applications. “In 1981, we were one of the first companies in Italy to install a clean room for the production of filter elements ", says Engr. Bea. “Of course, the cleanroom has been constantly adapted to the changing needs; the last major innovation in 2011, when we completed the expansion and modernization of the spaces. We believe that filtration processes are increasingly essential to ensure the high quality of products on the market"

Discover more on www.bea-italy.com

Bea Technologies Spa

Phone +39 02 339 271 | Fax +39 02 339 0713 | info@bea-italy.com | www.bea-italy.com

Phone +39 02 339 271 | Fax +39 02 339 0713

info@bea-italy.com | www.bea-italy.com