Cover Story

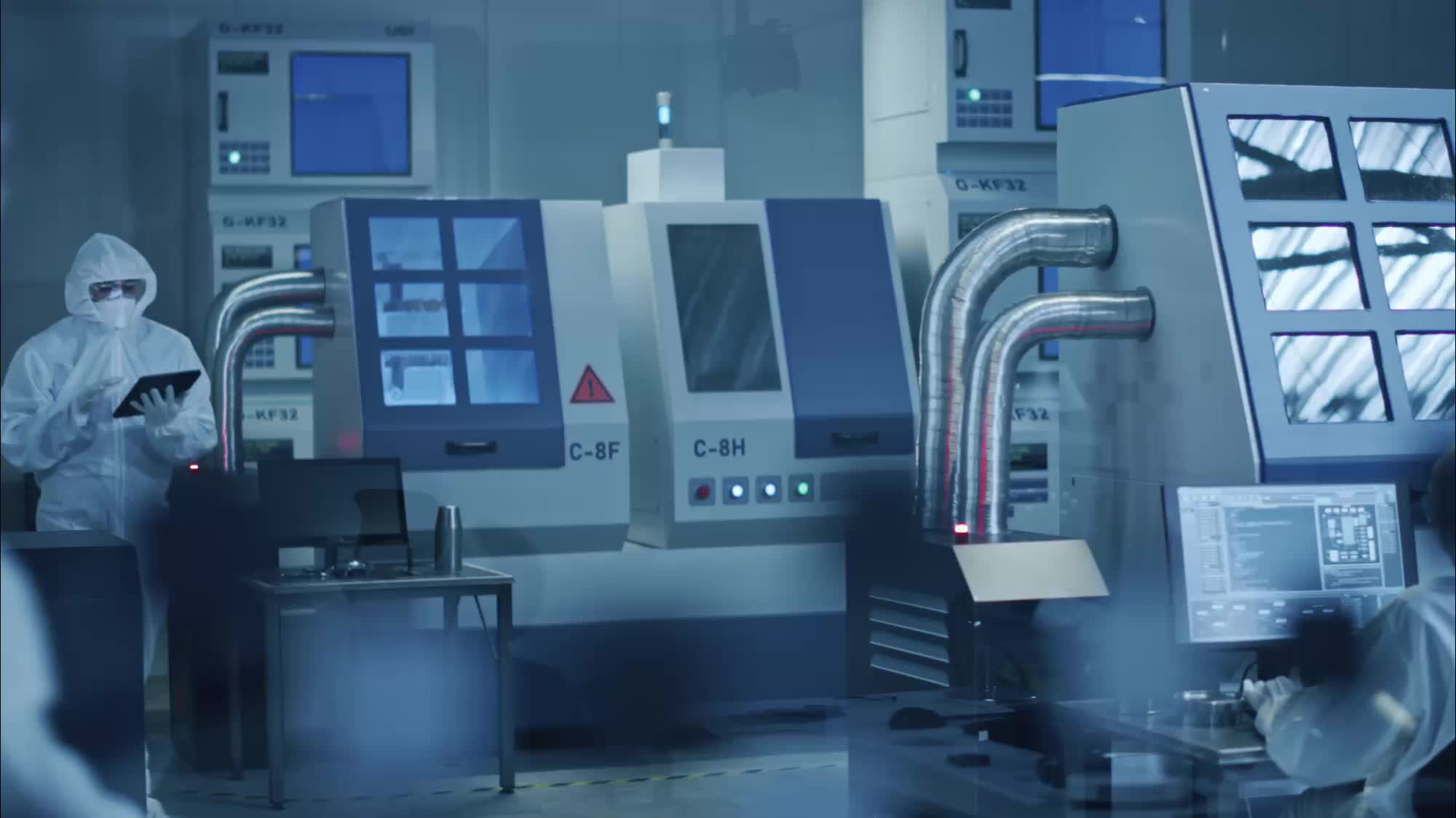

Cleanrooms reimagined: Inside pharma manufacturing’s new era

As biopharmaceutical manufacturing faces tighter regulations and the emergence of advanced therapies, cleanroom design is being fundamentally reshaped. From modular construction to robotics and smart ventilation, innovation is driving greater efficiency and contamination control. Gareth Macdonald outlines.

Main video supplied by gorodenkoff/Creatas Video+ / Getty Images Plus via Getty Images

Cleanliness is critical in biopharmaceutical manufacturing. Measures to ensure medicines are free of contaminants are vital, as are systems that contain and protect the raw materials from which therapies are made.

Historically, drug companies have used cleanrooms – dedicated areas within the manufacturing facility where products and raw materials are contained and operator handling is minimized – to reduce the risk of contamination.

Early cleanrooms were straightforward: a closed off area with distinct entrances and exits as well as a unidirectional air handling system. In recent years, however, designs have started to change as industry priorities have shifted.

Regulatory evolution

In part, the shift reflects changing regulatory expectations. In Europe, cleanrooms are covered by EU GMP Annex 1, which introduced new rules for particle counts, gowning, pressure differentials and validation processes when it came into force in 2024*1.

Similarly, in the US, the recent draft version of 21 CFR Parts 210/211*2 introduced the requirement that cleanrooms have fewer than 352,000 particles >0.5 micron per cubic meter and 60HEPA filtered air changes an hour.

This evolving regulatory landscape has changed how drug firms interact with engineering contractors says Alan Lambert, marketing manager at cleanroom and process integration provider, Advancetec LLC.

“Firms are asking for much more integration, technology, and collaboration than in years past,” notes Lambert, adding that clients routinely ask for detailed models and project -wide interactive planning sessions.

Cell and gene therapies

Another change driver for the cleanroom sector has been the commercial emergence of therapeutic modalities such as cell and gene therapies.

For these therapies, which involve living cells and cannot undergo terminal sterilisation or standard filtration, contamination control becomes even more critical than in the manufacture of conventional protein-based biologics.

“The cleanroom needs of facilities making cell and gene therapies are different in terms of scale, adaptiveness and systems approach but, ultimately, they are all seeking certainty of cost, schedule, and performance,” says Lambert.

Modular cleanrooms

Another emerging trend is the use of stand-alone, modular cleanrooms.

Classical cleanrooms are often referred to as being “stick built,” made from individual parts on site using traditional construction methods. They can take 12 to 18 months to complete, with construction often involving multiple contractors.

Modular cleanrooms, by contrast, are prefabricated units, built off-site and then shipped to the manufacturing facility. Construction typically takes three to six months, which represents a significant time saving. In addition, because they use standard components, they can be easily refigured to adapt to changing needs.

There are a variety of challenges when it comes to designing and building cleanrooms and they vary from project to project.

Lambert told us, “Biopharma clients have fully embraced modular finishes, off-site prefabrication, and modularisation of systems and racks to accelerate project schedules while improving safety, quality, and finished outcomes.”

The shift is also helping the engineering sector streamline design and production according to Lambert, who said, “There are a variety of challenges when it comes to designing and building cleanrooms and they vary from project to project."

“However, there are common difficulties such the limited availability of skilled resources and supply chain complexity. And these are driving the use of off-site prefabrication.”

Some drug firms are taking the modular concept even further and foregoing the facility in favour of stand-alone, cleanroom manufacturing units – often called “pods.”

However, while pods offer advantages - like in-hospital, at-bedside production - use to date has been limited, according to Lambert, who highlights pods are a fraction of the market and are not moving the needle in the industry.

Advancing tech

The types of technologies used in cleanrooms are also starting to change, again in response to evolving regulations.

For example, EU GMP Annex 1 suggested robotics could replace manual handling steps to protect products. The idea is that robots could reduce the risk posed by “extraneous sources of endotoxin/pyrogen, particulate and microbial contamination such as personnel, materials and the surrounding environment.”

Some companies have taken the advice. Both Pfizer and AstraZeneca have discussed using robotics in sterile manufacturing.

And analysts predict such systems will soon be more common. According to a recent study, “At the pharmaceutical level, the revolution is only beginning. Robotics is already widely used at the secondary packaging stage, but the coming years will see massive robot adoption in aseptic manufacturing environments as well.”

Robotics is already widely used at the secondary packaging stage, but the coming years will see massive robot adoption in aseptic manufacturing environments as well.

Ventilation systems are another area of innovation. A study looking at 185 cleanrooms of different sizes and classifications found a growing number of companies are introducing air volume control to cut energy consumption.

The authors noted, “The implementation of fresh air volume control showed a reduction of 8.87% in fan energy consumption, equivalent to a decrease of 46,666 units of air change per hour annually."

“This decrease in units was accompanied by a substantial reduction in fan waste, amounting to 203,399.1 kWh, and saving more than €49,055.8 per year using pressure gradient control strategies in the ventilation system.”

And advances in robotics, ventilation systems, containment and bioprocessing technology – combined with engineering expertise - are likely to continue influencing cleanroom design according to Lambert.

“Using AI as a predictive tool for schedule, progress and project controls is certainly helping. However, mission critical cleanrooms require segment expertise, years of experience, and a committed team of professionals to make happen,” says Lambert.

“What we see winning are nimble highly responsive models that leverage technology, prefabrication, and efficiencies without compromising on customisation and being purpose built.”