Features

- Single side or double side simultaneously on any shape & size containers.

- Speed up to 100-200-300 containers/min.

- Digital Servo Technology.

- Two label dispensers operates independently which allows different size of label application on either side.

- Unique spring loaded twin worm system virtually eliminated the use of any tools making it toll-less operation

- Spring action feed warm / feed screw ensures high safety to containers in case of toppling down does not damage.

- 3 Axis label dispensers allows any degree of label dispensing possible for any shape & bottle.

- Aprat form feed screw system machine can be supplied with belt orientation system for multi product handling without change part.

- Very unique notch orientation system for registered/fix position of label is possible with us.

TECHNICAL SPECIFICATIONS

- Pouch Type : Center Seal Pillow type

- Pouch Size Length : 60 to 300mm

- Width : 35 to 120mm

- Height : 10 to 70mm

MACHINE SPECIFICATIONS

Overall Dimensions (LxWxH): 4500 x 1000 x 1700mm (approx.)

Net Weight: 1000kg

Technical Data

- Output / min : 100-200-300 Pouches/Min

- Feeding System : Automatic Feeding

- Pouch Length : Automatic through Servo

- Cutting Length : Automatic through Servo

- Operating & Control Panel: Touch Screen HMI with PLC

- Temperature Controller : PLC based

Roll width : Maximum width 380 mm. / Minimum width 150 mm.

Standard Features

Standard Features

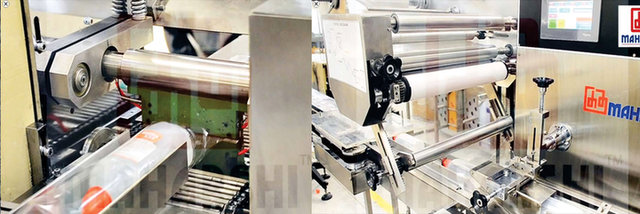

Automatic Horizontal Flow Wrap Machine is a versatile machine, which van wrap cylindrical, cubical and irregularly shaped solid products like I.V. fluid Bottle / Soap /Bearing / Disposable Syringe / Pencil Cells / Piston Rings / Spark Plug / Plastic Spoon / Pre-Filled Pouches / Scrub Pads and Similar Products in pillow pack pouch

The machine is an operator friendly machine with a speed range of 200 pouches per minute (speed can vary depending upon product size & packing material).

The machine comes with features like automatic pouch length adjustment mechanism, adjustable forming unit for a wide range of roll width, which ensure short change over times as well as minimum change parts. Machine can be provided with an optional attachment like coding unit, overload clutch etc. (at an extra cost)

UTILITIES:

Power Supply : 220/240 V AC, 50Hz, Single Phase,

Stabilized (Through 3 KVA, CVT, or in

Client Scope)

Rusty Nelson • (630) 776 - 2459 • Rnelson@djausa.com