LAUDA

WORLD PREMIERE

AT ACHEMA

World market leader unveils brand new temperature control devices at leading trade fair

Lauda-Königshofen, June 11, 2018 – ACHEMA is regarded as the most important meeting place for the process and laboratory technology industry. This was the 21st occasion on which LAUDA DR. R. WOBSER GMBH & CO. KG had exhibited at this leading international trade fair. This year, the world market leader presented its entire newly redesigned product range and a whole raft of new products to an international audience of specialists: new process thermostats and the Integral product line, plus new Ultracool process circulation chillers with intuitive operating concepts. The first LAUDA cloud-enabled temperature control devices underscore this temperature specialist's determination to actively help shape the digital transformation of its industry. Visitors from all over the world were able to get a close look at LAUDA's newly redesigned equipment for the first time over the course of the five days of the trade fair. This important event will no doubt have had the same worldwide significance and impact as the brand's relaunch earlier in the year.

Efficient process thermostats with intuitive operation

The high-performance process thermostats in the Integral product line have been an essential part of LAUDA's worldwide portfolio since the year 2000. The entire product line was technically revamped and brought into the digital age for the product presentation at ACHEMA. For instance, the models in the T and XT series have an intuitive operating concept that allows monitoring and control via a smartphone or tablet. Alternatively, a modern OLED display allows straightforward operation directly on the device.

LAUDA's Integral T process thermostats ensure effective control of external temperature control processes in the temperature range from -30 to 120°C. Integral T process thermostats with a reduced footprint have an adjustable heating and cooling capacity and small internal volume that enables fast temperature changes. Thanks to its open hydraulic system, the device vents quickly and without any functional restrictions, and is thus ideal for temperature controlling processes with frequent changes of consumer or item under test. Classic application areas include controlling reactions or climate simulations. LAUDA's extremely dynamic, high-performance Integral XT process thermostats, on the other hand, operate with a cold oil blanket according to the flow principle and make it possible to use just one temperature control medium across the entire temperature range from -90 to 220°C. Thanks to an electronically controlled, magnetically coupled pump, the flow rate can be optimally thermally set for the requirements of pressure-sensitive consumers, as well as applications with high hydraulic resistance. An internally connectable bypass also increases flexibility.

LAUDA presented its newly redesigned product lines at ACHEMA 2018. Process thermostats in the Integral T series can be intuitively controlled using mobile devices.

Integral XT750 process thermostat in the new LAUDA design look.

LAUDA presents the world's first cloud-enabled circulation chiller

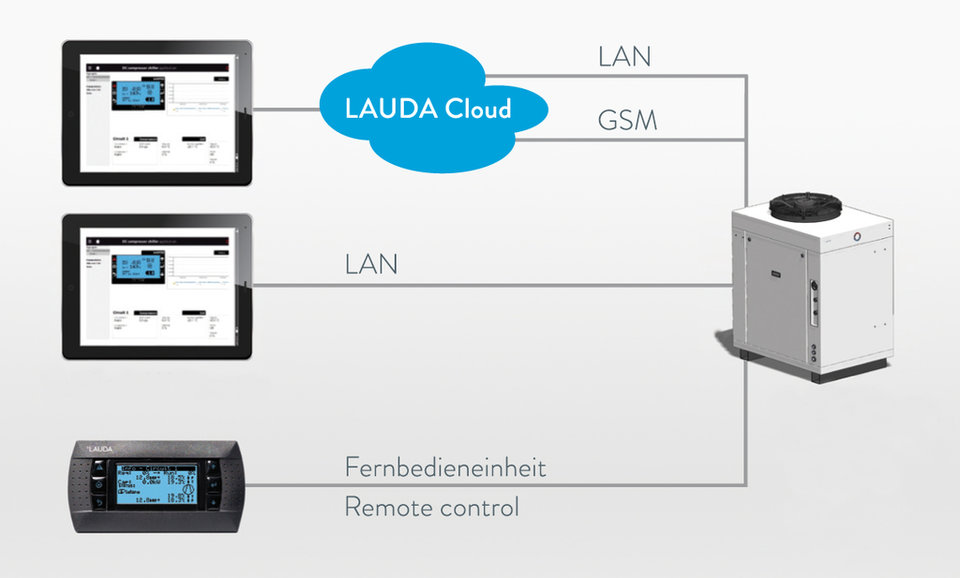

Thanks to the greater focus it has been placing on increasingly digitized work processes, LAUDA introduced new devices in its Ultracool line at ACHEMA. Newly developed from scratch and with a clear emphasis on energy efficiency, the new Ultracool devices reduce operating costs by as much as 50 percent. In future, remote monitoring will allow diagnostics and preventive maintenance of chillers. This is made possible for the first time ever in LAUDA's history by connection to the LAUDA cloud or an internal web server.

The advantages of digital technology are obvious. Support and troubleshooting can be carried out from any computer that has Internet access, thereby reducing downtime significantly. Important key performance indicators of Ultracool circulation chillers can be checked at any time, to monitor the efficiency or performance of relevant components, for instance. Distributed access to the historical data of every device in the LAUDA cloud enables predictive and preventive maintenance. As an option, the new circulation chillers can be equipped with an external control unit. LAUDA Ultracool devices comply with Ecodesign Directive 2009/125/EC and are individually customizable with many options. Ultracool devices have a high temperature stability of ±0.5 K and a working temperature range of -10 to 35°C.

A glimpse into the future: LAUDA presents its new equipment design

LAUDA launched its brand new, award-winning brand image in early 2018, and took the next logical step – making an appearance at this year's ACHEMA. All of the world market leader's temperature control technology product lines, from LAUDA Aquiline water baths through to circulation and process thermostats, such as the LAUDA Kryoheater Selecta, have been upgraded to reflect the new styling and unified into a single strong, logical and consistent system.

The LAUDA Group's product range has been completely transformed in cooperation with Hamburg design studio, open fields, within less than two years. Prof. Detlef Rhein, an open fields partner, articulates the basic idea behind this development "Our primary intention was not to design products but to design smart, future-proof technology.

The new look had to have functional and interactive qualities, rather than simply being a shell. A device has to be considered in the context of complex interfaces and relationships rather than in isolation."

The new stylistic idiom of LAUDA's portfolio is more than just a matter of design. Factors such as ease of service access, intuitive operation and simplified installation were some of the strategic objectives during the design process. The number of casing parts was minimized in the case of the new Integral devices; this has clear benefits for servicing and installation. The devices' electronic and mechanical ports were consolidated and consistently graphically coded. The user interface is no longer integrated in the casing in order to anticipate future device-independent operating methods, such as the use of mobile terminal devices. "Design is always a child of its time," explains Prof. Rhein.

"The new LAUDA design is significantly pared down, but still convincing in terms of details and standards. This explicitness will remain tangible and relevant for a long time."

LAUDA Ultracool circulation chillers are cloud-enabled for the very first time in LAUDA's history. This means that key performance data of circulation chillers can be controlled and checked locally at any time.

The new Ultracool devices support remote access via the cloud or an internal web server.

Customer-specific heating and cooling systems at ACHEMA 2018

LAUDA's Heating and Cooling Systems Division had a stand of its own at the most important trade fair for the process industry. In Hall 5.1, Booth B76, trade visitors experienced the "Modular Engineering" principle, according to which LAUDA has been planning and building process cooling units, heat transfer systems and secondary circuit units to meet its customer's precise requirements on a process-oriented, tailor-made, and fully compliant basis for more than 50 years.

LAUDA's comprehensive heating and cooling system product portfolio ranges from monofluid systems down to -150°C with liquid nitrogen, through to molten salt systems for operating temperatures up to 550°C, from refrigerating machines to fired heaters for services in the MW range, and from single devices through to extensive temperature control concepts for entire production plants.

The European F-gas Regulation was an important topic at ACHEMA. Operators of older refrigeration systems need to ask themselves whether, given the diminishing availability of certain refrigerants, the operation of their plant will remain secure in the future. The construction of new plant will need to cater for future operation using environmentally friendly refrigerants. LAUDA heating and cooling systems are certified according to DIN EN 378 and, thanks to comprehensive compliance with the European F-gas Regulation, ensure the smooth operation of any refrigeration system. LAUDA service engineers advised specifically interested trade visitors to ACHEMA on issues such as sustainable retrofitting, the modification of old systems or future-proof planning and implementation of new refrigeration projects.

About LAUDA

We are LAUDA - the world leader in precise temperature control. Our thermostatic circulators and heating and cooling systems are at the heart of many applications. As a complete one-stop supplier we guarantee the optimum temperature in research, production and quality control. We are your reliable partner, particularly in the fields of automotive, chemical/pharma, semiconductor and laboratory/medical technologies. We have been inspiring our customers for more than 60 years with our competent mentoring and innovative, environmentally-friendly concepts - new every day and all over the world.

Contact LAUDA

LAUDA Technology Limited

Phone: +44 1780 243118

E-mail: info@lauda-technology.co.uk

Website: www.lauda-technology.co.uk

Back to top