Dry granulation has been known for decades.

The main benefit is a lower cost of operation compared to wet granulation. New solutions now exist to easily test dry granulation on small scale early in the development process which was

not feasible before.

WHY IS DRY GRANULATION SO

POPULAR THESE DAYS?

Granulation of pharmaceutical

powder is often required to

prevent segregation of the Active

Pharmaceutical Ingredient (API). It

also enhances the blend flowability,

which is critical to ensure consistent

tablet mass (weight) on rotary tablet

presses. It is also used when API is

heat and/or moisture sensitive and

therefore wet granulation should be

avoided. But most interestingly, it is

also a real continuous granulation

process, which is a big trend these

days. In case of high potent drugs,

it is much easier to contain a

roller compactor than a fluid bed

dryer. One has to point out that

in the past decade, equipment

manufacturers have introduced

more instrumentation and advanced

control systems, such as Gerteis or LB

Bohle to name a few, allowing a more

consistent ribbon density through a

gap control loop system acting on the

feeding rate.

WHICH SOLUTIONS EXIST TODAY

TO SCREEN FORMULATIONS FOR THEIR

SUITABILITY TO DRY GRANULATION?

Formulation scientists have to

screen several formulas to ensure

proper Quality Attributes, such as

tablet breaking force, disintegration

time and dissolution profiles. R&D

roller compactors have usually large

rolls, which means that the required

quantity of API to run a test is fairly

high, a main hurdle at the early stages

when the API is not available in large

quantity, not to mention the cost per

kilo. One solution could have been to

use a roller compactor with small rolls

in order to use a smaller quantity of

material. However, these small rolls

cannot achieve the densification of

large rolls used in production and

this can yield to false negatives when

considering the material ability to

be dry granulated. That is the reason

why people are looking for alternative

methods to assess the feasibility of

dry granulation in the early stages of

the development.

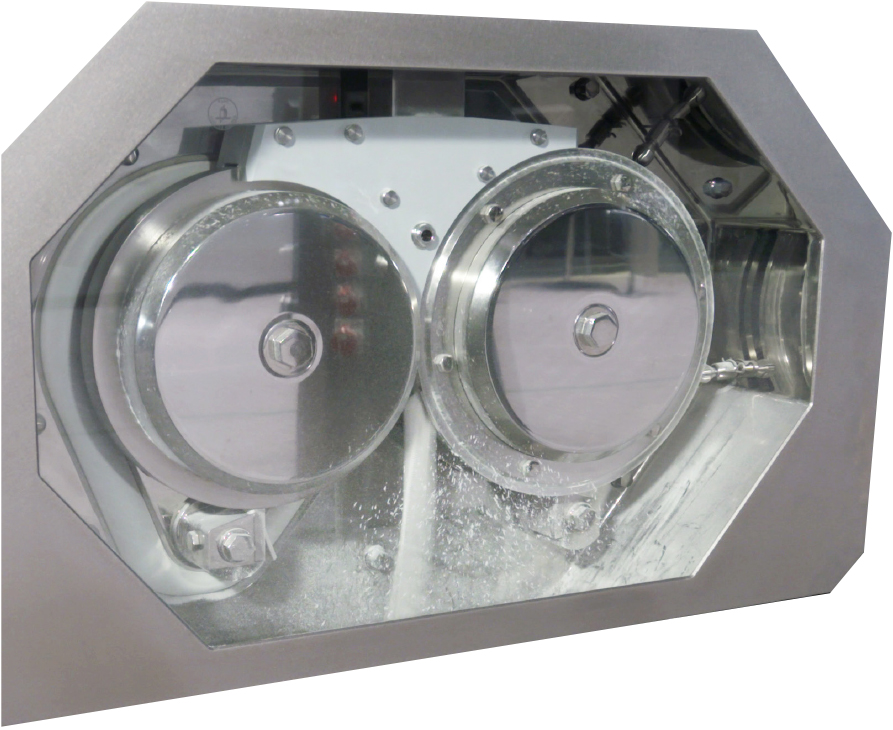

Roller Compactor

CAN YOU DESCRIBE IN MORE DETAILS

THIS MATERIAL SPARING METHOD?

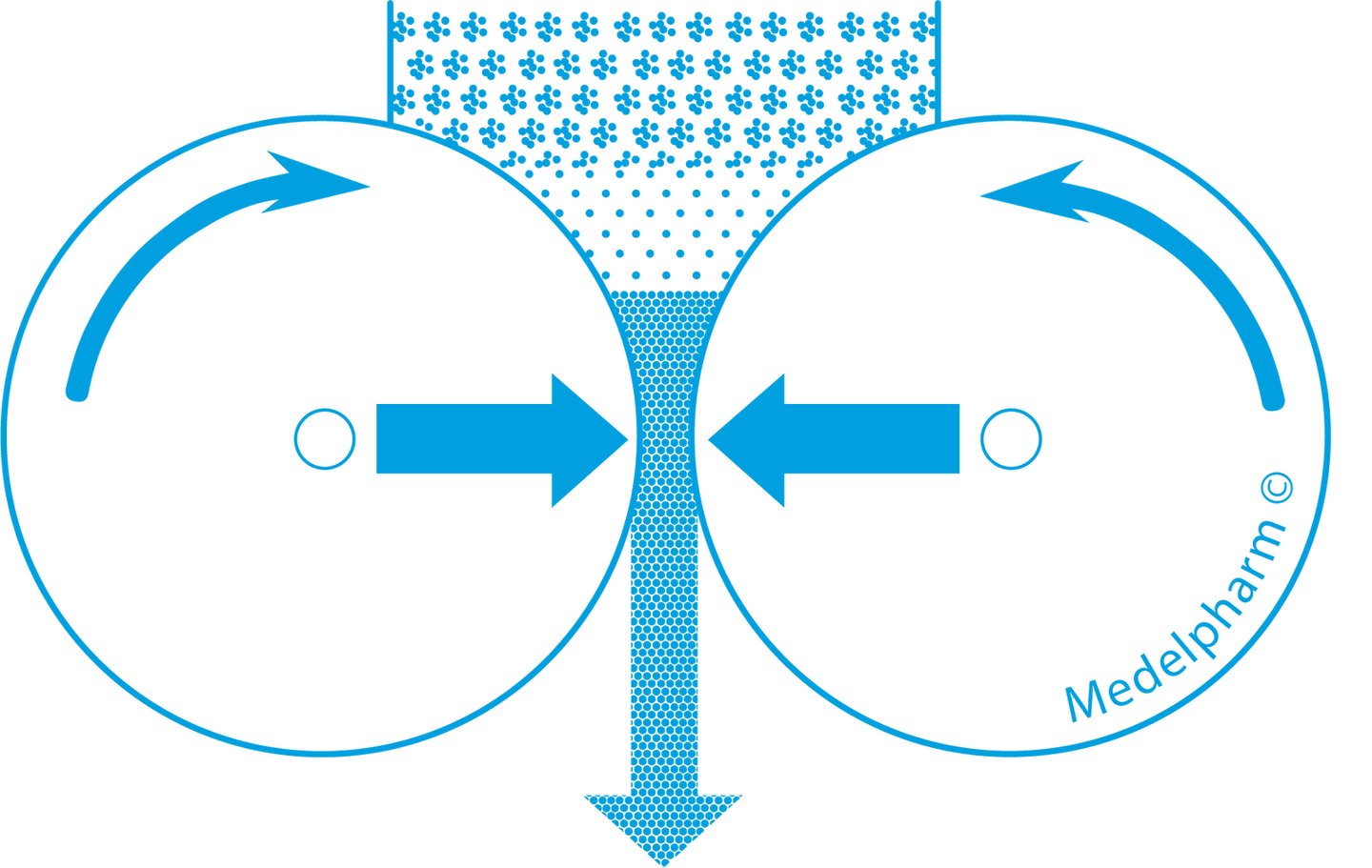

This method was introduced

back in 2004 in a publication

from Pfizer [1] in the USA. Their

proof of concept was to show that

density-pressure plots were identical

between compacts made on a single

punch press and ribbons made on

real roller compactor. Both punches

on the single punch press, a “roller

compaction simulator” to be precise,

was following a sine-wave path to

mimic the compression dynamics

occurring between the rolls of roller

compactors. The rolls diameter and

rolls speed were taken into account

to be as close as possible to the

production process.

To be more precise, the relative

density, also called solid fraction,

was used instead of the density. This

solid fraction is calculated by dividing

the ribbon density by the powder

true density, a parameter generally

measured with a helium pycnometer.

Solid Fraction =

It is important to note that the

pressure measured on a single punch

press is not directly comparable with

the pressure on a roller compactor.

Back in 2004, Pfizer just manually

fitted the compressibility curves

together to have a correlation

between the pressures on both

equipment units

Density

Powder true density

This method was introduced

back in 2004 in a publication

from Pfizer [1] in the USA. Their

proof of concept was to show that

density-pressure plots were identical

between compacts made on a single

punch press and ribbons made on

real roller compactor. Both punches

on the single punch press, a “roller

compaction simulator” to be precise,

was following a sine-wave path to

mimic the compression dynamics

occurring between the rolls of roller

compactors. The rolls diameter and

rolls speed were taken into account

to be as close as possible to the

production process.

To be more precise, the relative

density, also called solid fraction,

was used instead of the density. This

solid fraction is calculated by dividing

the ribbon density by the powder

true density, a parameter generally

measured with a helium pycnometer.

Solid Fraction =

Density

Powder true density

It is important to note that the

pressure measured on a single punch

press is not directly comparable with

the pressure on a roller compactor.

Back in 2004, Pfizer just manually

fitted the compressibility curves

together to have a correlation

between the pressures on both

equipment units

Density

Powder true density

This method was introduced

back in 2004 in a publication

from Pfizer [1] in the USA. Their

proof of concept was to show that

density-pressure plots were identical

between compacts made on a single

punch press and ribbons made on

real roller compactor. Both punches

on the single punch press, a “roller

compaction simulator” to be precise,

was following a sine-wave path to

mimic the compression dynamics

occurring between the rolls of roller

compactors. The rolls diameter and

rolls speed were taken into account

to be as close as possible to the

production process.

To be more precise, the relative

density, also called solid fraction,

was used instead of the density. This

solid fraction is calculated by dividing

the ribbon density by the powder

true density, a parameter generally

measured with a helium pycnometer.

Density

Powder true density

Solid Fraction =

Density

Powder true density

Destiny

Powder true density

It is important to note that the

pressure measured on a single punch

press is not directly comparable with

the pressure on a roller compactor.

Back in 2004, Pfizer just manually

fitted the compressibility curves

together to have a correlation

between the pressures on both

equipment units

Powder true density

HOW DO YOU PROVE THAT THIS

METHOD GIVES SIMILAR RESULTS

AS ON A ROLLER COMPACTOR?

F

irst, like any material-sparing

methods, mimicking the dry

granulation process on a single punch

press has some limitations. The

feeding system, de-aeration, pressure

gradient along the ribbon width, the

roll surface and shape are actually

not taken into account. That’s sounds

like a lot, but this method is actually

the only method to evaluate the dry

granulation process at early stages.

The dry granulation is a slow

symmetric compaction process. Many

formulators were using eccentric

presses trying to predict the powder

ability to be dried granulated

with more or less success, as this

compaction is asymmetric and

therefore does not fully mimic a roller

compactor.

More recently Sanofi published

research performed on a Medelpharm

rotary press simulator at very slow

speed with the benefit of symmetric

compaction. Their findings were

already much more satisfactory. [3]

With the new STYL’One Tableting

Instrument, this method was greatly

improved. This was achieved by

implementing a mathematical model

to compute, from the pressure

measured on the STYL’One, the

equivalent hydraulic pressure (or

specific compaction force) that should

be entered on a roller compactor to

reach the same solid fraction. This

method is called “hybrid modelling”,

since it uses a mathematical model

combined with real compacts made

on a single punch press. Recently, the

University of Düsseldorf published a

paper [2] using different excipients

(brittle, plastic). They've shown that

compacts, called ribblets (a neologism

created from ribbon + tablet) made

on a STYL'One and ribbons made on

a Gerteis roller compactor had similar

relative density.

Even with the limitations listed

earlier, this material-sparing method

remains the most effective method

available to assess dry granulation

with a small amount of material. It

has been adopted by pharmaceutical

companies across the globe as one

of their reference method to decide if

dry granulation is a feasible process

and to speed up their design of

experiments (DoE) when scaling-up to

a commercial-size roller compactor.

WHAT ARE THE BENEFITS OF USING

STYL'ONE TABLETING INSTRUMENT TO

ASSESS A DRY GRANULATION PROJECT?

The philosophy of STYL’One is

to help formulation scientists

to easily implement this method,

which is integrated in the software

controlling the press. The formulator

can choose from a library of branded

roller compactors, such as Gerteis,

LB Bohle, Fitzpatrick, Alexanderwerk,

Vector-Freund, Hosokawa Bepex.

Each profile bears all the physical

characteristics: roll diameter and

width, roll speed, gap range, specific

compaction force or hydraulic

pressure. Ribblets can be produced

in a desired thickness (gap) and

pressure. If the True Density is known,

the operator can simply select a

desired Solid Fraction, typically

between 0.6 and 0.8, and a thickness

(gap) and STYL'One make the ribblets

within specifications.

The key benefit of this method

is the use of an extremely small

quantity of API at the early stage of

development.The formulator can

design a small DoE with, for instance,

3 solid fractions at the same gap

and different formulations. Then,

make a few ribblets, mill them to

obtain dry granules, and recompress

them into tablets, which can be

characterized with tablet breaking

force, disintegration time and

dissolution profiles. All of this will help

the selection of the right formulation.

This method saves time and mitigates

the risks of scale-up to a real roller

compactor. It allows you to select the

most adequate formulation and gives

good approximation of the process

parameters to be used on the roller

compactor to achieve the desired

Quality Attributes.

[1] Zinchuk, Andrey V., Matthew P. Mullarney, and Bruno C. Hancock.

“Simulation of Roller Compaction Using a Laboratory Scale

Compaction Simulator.” International Journal of Pharmaceutics 269,

no. 2 (January 2004): 403–15.

https://doi.org/10.1016/j.ijpharm.2003.09.034.

[2] Reimer, Hannah L., and Peter Kleinebudde. “Hybrid Modeling of Roll

Compaction Processes with the STYL’One Evolution.”

Powder Technology, February 2018.

https://doi.org/10.1016/j.powtec.2018.02.052.

[3] Bardet, Lionel. “Compression Simulator (Stylcam) as a Modeling

Tool for Roller Compaction Process.” presented at the Journée

d’information APGI, Lyon, October 15, 2013.

http://www.tablet-tech.com/slides.